Enhancing Concrete Structures with Welded Wire Mesh

When it comes to constructing durable and long-lasting concrete structures, one essential element that often goes unnoticed is welded wire mesh. This unassuming material plays a crucial role in reinforcing concrete, improving its strength, and preventing cracks.

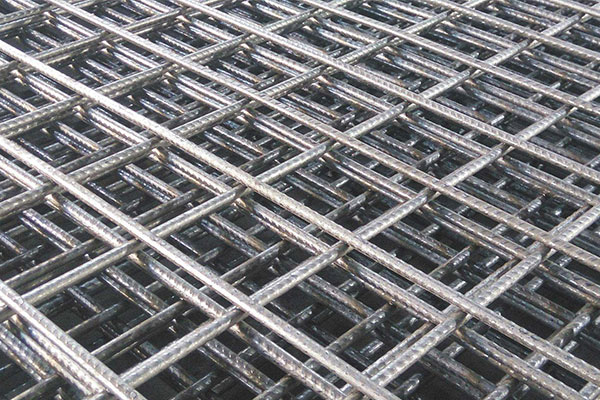

What is Welded Wire Mesh?

Welded wire mesh is a grid-like framework composed of steel wires that are welded together at their intersections. These meshes come in various sizes, shapes, and configurations, making them versatile for a wide range of construction applications. When used in concrete construction, they act as reinforcement to enhance the structural integrity of the concrete.

Benefits of Using Welded Wire Mesh in Concrete

- Improved Strength: One of the primary advantages of incorporating welded wire mesh in concrete is the significant boost in strength. The mesh helps distribute loads evenly, preventing the formation of cracks and enhancing the concrete’s overall strength.

- Crack Control: Concrete is susceptible to cracking due to factors such as temperature changes, shrinkage, and heavy loads. Welded wire mesh effectively controls cracking by providing tensile strength, which is particularly important during the early stages of concrete curing.

- Durability: Concrete structures reinforced with welded wire mesh are more durable and have a longer lifespan. This added durability ensures that the structure can withstand the test of time and environmental factors.

- Cost-Efficiency: By preventing cracks and enhancing strength, welded wire mesh reduces the need for costly repairs and maintenance in the long run, making it a cost-effective choice for construction projects.

- Flexibility: Welded wire mesh can be customized to meet specific project requirements. It comes in various thicknesses and grid patterns, allowing for flexibility in design and application.

Best Practices for Using Welded Wire Mesh in Concrete

- Proper Placement: Ensure that the welded wire mesh is correctly positioned within the concrete to maximize its effectiveness. It should be placed in the middle of the concrete slab or wall, away from the surface.

- Spacing and Size: The spacing and size of the mesh should be chosen based on the project’s specifications and engineering recommendations. Properly sized and spaced mesh provides the necessary reinforcement.

- Overlap Joints: When using multiple sheets of welded wire mesh, overlap the sheets by several inches to ensure continuity in reinforcement.

- Concrete Cover: Maintain the recommended concrete cover thickness over the welded wire mesh to protect it from corrosion and environmental factors.

- Professional Installation: It’s crucial to have trained professionals install the welded wire mesh to ensure it is placed correctly and securely within the concrete structure.

Conclusion

In the world of concrete construction, welded wire mesh plays a vital role in enhancing the strength, durability, and longevity of structures. By preventing cracks and improving structural integrity, it offers numerous benefits that make it a valuable addition to any concrete project. When used correctly and in accordance with industry best practices, welded wire mesh becomes an indispensable component in creating resilient and enduring concrete structures.

Get Quality Welded Wire Mesh

RoadSky is a welded wire mesh manufacturer and supplier from China with rich experience and can be customized according to customer requirements to meet the different needs of customers. If you are looking for welded wire mesh for your project, you can contact us directly for more information.