The Role of Welded Wire Mesh in Concrete Construction

In the realm of modern construction, ensuring the longevity and structural integrity of buildings and infrastructure is paramount. One indispensable element that contributes significantly to achieving these goals is welded wire mesh in concrete. This innovative construction material has proven to be a game-changer, providing enhanced strength, durability, and overall performance in concrete structures. In this article, we will explore the various benefits and applications of welded wire mesh in concrete construction.

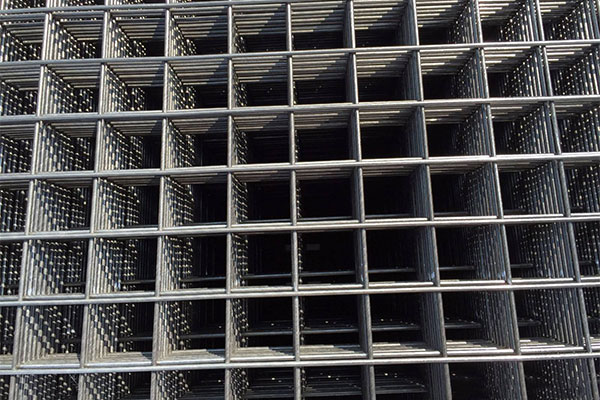

The Basics of Welded Wire Mesh:

Welded wire mesh is a grid of interconnected steel wires welded together at regular intervals to form a flat, flexible sheet. This mesh is available in various configurations, with different wire diameters and mesh sizes to meet the specific requirements of construction projects. The mesh is typically made from low-carbon steel, which ensures a high level of strength and ductility.

Benefits of Welded Wire Mesh in Concrete:

1. Reinforcement of Concrete Structures:

Welded wire mesh acts as a reinforcement in concrete, providing additional strength and preventing the development of cracks. This reinforcement is particularly crucial in areas with high seismic activity or heavy loads.

2. Crack Control and Prevention:

Concrete tends to develop cracks over time due to various factors such as shrinkage, temperature fluctuations, and loading. Welded wire mesh effectively controls and minimizes the development of cracks, ensuring the structural integrity of the concrete.

3. Increased Flexural Strength:

The inclusion of welded wire mesh significantly enhances the flexural strength of concrete. This is crucial in applications where the concrete is subjected to bending or flexing forces, such as in suspended slabs or beams.

4. Uniform Load Distribution:

Welded wire mesh helps distribute loads evenly across the concrete surface. This uniform distribution of loads minimizes localized stress points, reducing the risk of structural failures and ensuring a more resilient and durable construction.

5. Corrosion Resistance:

Many welded wire meshes are coated with corrosion-resistant materials, providing an added layer of protection against environmental factors. This feature is particularly advantageous in marine or industrial environments where corrosion poses a significant threat to the longevity of concrete structures.

Applications of Welded Wire Mesh in Concrete Construction:

Road and Bridge Construction:

Welded wire mesh is widely used in the construction of roads and bridges to reinforce concrete pavements, ensuring their ability to withstand heavy traffic loads and environmental stressors.

Residential and Commercial Buildings:

In the construction of residential and commercial buildings, welded wire mesh is employed to reinforce slabs, walls, and other structural elements. This reinforcement enhances the overall stability and longevity of the structures.

Precast Concrete Products:

Welded wire mesh finds extensive use in the production of precast concrete products, such as panels and pipes. The reinforcement provided by the mesh ensures the durability and structural integrity of these precast elements.

Conclusion:

Welded wire mesh in concrete construction is a versatile and essential component that plays a pivotal role in enhancing the strength, durability, and overall performance of structures. Its applications range from residential buildings to large-scale infrastructure projects, making it a cornerstone in modern construction practices. As builders and engineers continue to prioritize longevity and resilience in construction, the integration of welded wire mesh will undoubtedly remain a key strategy for achieving these goals.