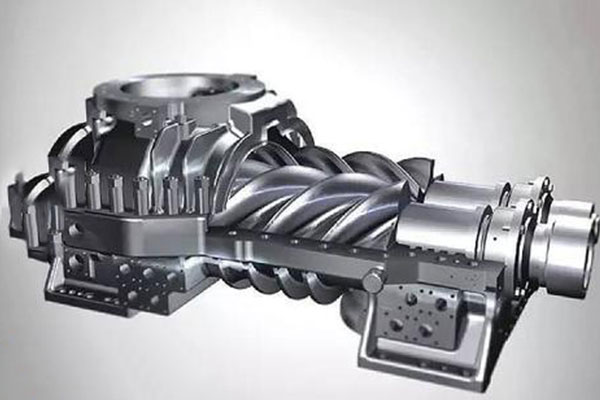

How to Choose the Right Rotary Screw Air Compressor?

Investing in a rotary screw air compressor is a significant decision for any industrial or commercial operation. Selecting the right rotary screw air compressor can greatly impact efficiency, productivity, and long-term operational costs. In this guide, we’ll walk you through the key factors to consider when choosing the perfect rotary screw air compressor for your specific requirements.

1. Understand Your Air Demand:

The first step in selecting the right rotary screw air compressor is to determine your air demand. Consider the maximum and fluctuating air requirements of your applications. This will help you choose a compressor with the appropriate horsepower and cubic feet per minute (CFM) ratings to meet your needs.

2. Evaluate Compressor Size and Capacity:

Rotary screw air compressors come in various sizes and capacities. It’s crucial to choose a compressor that aligns with the size of your operation. An oversized compressor may lead to excessive energy consumption, while an undersized one may struggle to meet demand. Evaluate the compressor’s capacity in relation to your peak air demand for optimal performance.

3. Consider Operating Pressure:

Different applications require different operating pressures. Ensure that the rotary screw air compressor you choose can provide the necessary pressure for your tools and equipment. Be mindful of any potential future needs that might require higher pressure.

4. Energy Efficiency:

Energy efficiency is a critical factor in reducing operational costs. Look for compressors with advanced features such as variable speed drives (VSD) that adjust the motor speed to match the air demand. This not only saves energy but also extends the lifespan of the compressor.

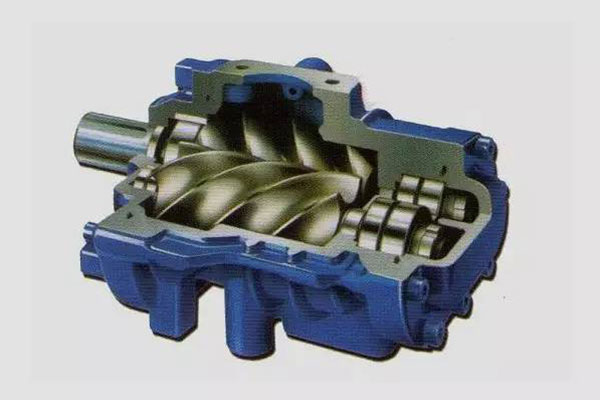

5. Check for Reliability and Durability:

Reliability and durability are paramount when selecting a rotary screw air compressor. Consider the reputation of the manufacturer, the build quality of the compressor, and the availability of service and maintenance support. Investing in a reliable and durable compressor can prevent unexpected downtime and repair costs.

6. Noise Levels:

Consider the noise levels of the rotary screw air compressor, especially if it will be operating in a noise-sensitive environment. Look for compressors with low dB ratings or those equipped with noise-reducing features to create a more comfortable working environment.

7. Maintenance Requirements:

Understanding the maintenance needs of the compressor is essential for keeping it in peak condition. Choose a compressor with user-friendly maintenance features, easy access to components, and a clear maintenance schedule. Regular maintenance will prolong the life of the compressor and ensure consistent performance.

8. Budget Considerations:

While it’s tempting to opt for the most affordable option, it’s crucial to balance cost with quality and performance. Consider the long-term operational costs, including energy consumption and maintenance, when making your decision.

Conclusion:

Choosing the right rotary screw air compressor involves a thorough evaluation of your specific requirements. By considering factors such as air demand, compressor size, operating pressure, energy efficiency, reliability, noise levels, maintenance requirements, and budget, you can make an informed decision that enhances the efficiency and productivity of your operation while minimizing long-term costs.